Select a province & language

Entrance to this website assumes you have read and agree to these Legal Terms and Conditions and the Privacy Policy.

Entrance to this website assumes you have read and agree to these Legal Terms and Conditions and the Privacy Policy.

Anyone who has seen the heavy fumes a transport truck emits, probably wouldn’t be surprised to learn that freight traffic is the second largest source of greenhouse gas emissions in Canada*. With efforts worldwide to improve the planet’s health and reduce greenhouse gas emissions, Toyota is more committed than ever to developing fuel-saving and alternative powertrain technologies.

As an industry leader of electrified vehicles, we have been investing in hydrogen fuel cell technology since the 1990s. We launched the Mirai in 2014, which is one of the world’s first mass market fuel cell electric vehicles and have since expanded the technology to freight vehicles through “Project Portal”.

Operated by hydrogen fuel cell technology, Project Portal is a concept vehicle that came to life, thanks to our engineers and technicians. Using two fuel cell stacks (borrowed from two Toyota Mirai vehicles) as their base, they created one of the world’s first OEM-built zero CO2 emissions heavy trucks in a Michigan garage.

The Class 8, heavy-duty, semi-truck moves cargos between depots in Southern California daily. The 670-plus horsepower truck is propelled by an electric motor, produces 1,325 lbs-feet of torque from two fuel cell stacks, and emits only water from the tailpipe.

The truck is strong and powerful, and its electric powertrain allows drivers to accelerate and transition smoothly. Curious to know how it drives in comparison to a conventional transport truck? Test drivers mention that it is quieter, easier to operate and more comfortable.

Traveling 320 kilometres per day, the truck refuels in between shipments at a hydrogen refueling station, where liquid hydrogen is converted into fuel. After 25 minutes of fueling, the hydrogen tanks are topped up with enough hydrogen fuel for the next day, and the Project Portal truck is ready to hit the road again.

While there are currently only 39 hydrogen fueling stations in California to date, Toyota has recently partnered with Shell to install more.

Eager to build and improve on the pilot project, Toyota analyzed the concept truck’s performance in both test facilities and the real world. Using our learnings as a guide, we got to work on the next version of the concept vehicle – also known as Project Portal 2.0.

The Beta model is noticeably improved, with an extended range of 500 kilometers per fill. It is also easier to maneuver and more versatile, with a new sleeper cab and a unique fuel cabinet combination.

Set to hit the roads in Fall 2018, Project Portal 2.0 is the next step in our mission to move beyond a proof of concept and set a new standard for transport trucks.

Both Project Portal 1.0 and 2.0 trucks are hydrogen fuel cell electric vehicles, which means they’re fueled by the most abundant element in the universe. Free of impurities and lighter than air, hydrogen fuel can be created from a variety of energy sources such as solar power, hydropower and methane gas.

Hydrogen can also be extracted from water through a process called electrolysis. An electrical current passes through water to create a chemical reaction that separates water’s two main elements: hydrogen and oxygen.

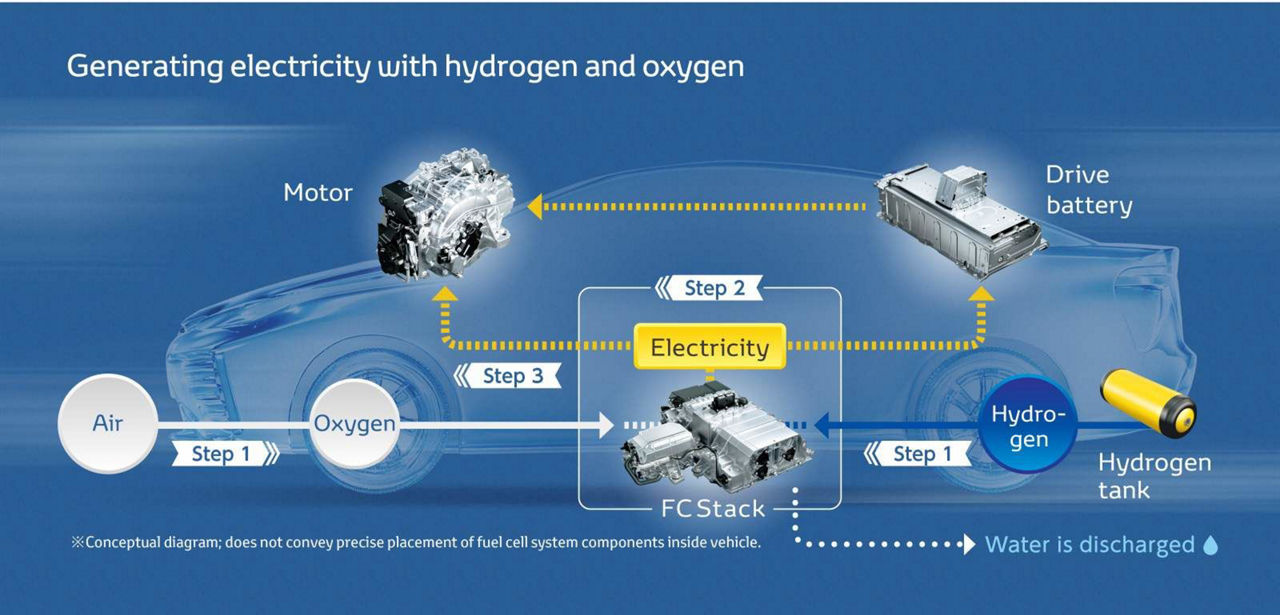

In hydrogen fuel cell electric vehicles, hydrogen gas is stored in the vehicle’s high-pressure hydrogen tanks. As oxygen enters the vehicle through the front intake grille, the oxygen and hydrogen meet in the fuel cell stack, where a chemical reaction creates electricity and water.

The electricity is then supplied to the motor, which is used to drive the wheels. The battery also stores some of this generated electricity, as well as recovered energy from braking. The battery then provides supplemental power to the electric motor. At the end, the tailpipe only emits water vapour.

As part of our dedication to hydrogen fuel cell technology, Toyota is constructing the world’s first megawatt-scale carbonate fuel cell power generation plant at the Port of Long Beach to supply all Toyota fuel cell vehicles moving through the Port with hydrogen fuel. The Tri-Gen is expected to open in 2020 and will use bio-waste to generate approximately 2.35 megawatts of electricity and 1.2 tons of hydrogen per day. Based in Long Beach, the proof-of-concept plant will also include one of the world’s largest hydrogen fueling stations.

We are also currently working with several Japanese governments to create a hydrogen supply chain powered by solar energy. The low-carbon energy produced will be used to power forklifts and reduce associated emissions at fruit & vegetable markets, factories and warehouses. Interested in learning more? Read up on hydrogen fuel cell technology.

*https://www.ec.gc.ca/indicateurs-indicators/default.asp?lang=en&n=f60db