Select a province & language

Entrance to this website assumes you have read and agree to these Legal Terms and Conditions and the Privacy Policy.

Entrance to this website assumes you have read and agree to these Legal Terms and Conditions and the Privacy Policy.

To put it simply, thermal efficiency of gasoline engines is how much of the potential energy in gasoline gets converted into power that can be used to move the vehicle. Internal combustion engines do this by injecting that gasoline in a fine spray in a mixture with air in the cylinders, the piston squeezing it into as small a space as possible and lighting it with a spark. When it ignites, it explodes and expands, pushing the piston back out with incredible force, and the pistons turn the crankshaft, which is connected to the transmission, which is connected to the drive shaft, which is connected to the wheels, with various parts and gears in between directing and controlling the power to make sure the wheels turn, but not so fast that they simply spin faster than the tires can handle.

During the combustion process, some of the power is lost to friction and excess heat, leaving the average gasoline combustion engine running at about 35% thermal efficiency. For more than a hundred years, ever since the combustion engine was invented, engineers have been working to reduce the energy wasted and converting as much of that energy in gasoline to moving the car (or running the sweet, cool breeze of your air conditioning).

Think of the top swimmers in the world at the Olympics, all competing at about the same efficiency, converting the energy in their muscles into motions that push them through the water. Sometimes those races can be incredibly close, like in 2008, when Michael Phelps set a record for gold medals in a single Games when he won eight golds, one of those races by a scant 0.01 seconds. Imagine if Phelps had developed a new kicking technique that converted one per cent more energy into a little bit more speed? He would have won easily instead of barely winning.

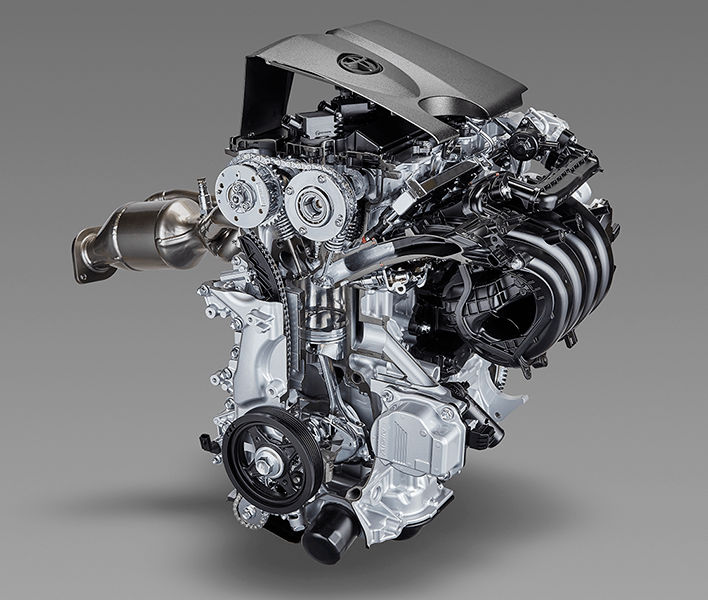

Well, the engineers at Toyota weren’t very satisfied with the performance of combustion engines, so they did something about it, and the results have been launched in their new line of Dynamic Force engines. They looked at every stage of the engine’s cycle and tried to find ways to make it not only more efficient in terms of saving gas, but also more thermally efficient in terms of converting that gasoline into more power. More efficiency AND more power? You won’t find many people that would argue with that proposition, and one of the key elements they improved was the combustion itself within the cylinder.

Toyota looked to Formula 1 for inspiration, using various technologies to achieve high-speed combustion. Three changes in particular have helped accomplish high-speed combustion, wherein the air-fuel mixture burns more completely and produces more power with every combustion: the angle of the intake valve, laser clad valve seats, and the proportions of the cylinder. The angle of the intake valve and shape of the intake port guide the air-fuel mixture in a specific pattern to spread it more evenly within the cylinder, so it combusts more quickly and more evenly, producing more power and less waste. The laser-clad valve seats allow for optimized valve angle and airflow direction to create “tumble flow,” a more controlled swirl pattern in the combustion chamber that distributes the air-fuel mixture more evenly ahead of the compression phase. A taller, narrower cylinder means the igniting mixture takes less time spreading across the cylinder, again speeding up that combustion moment, and more of its force pushing the piston down, which provides more torque and greater efficiency.

Toyota engineers didn’t just stop there, using additional tried-and-tested strategies to maximize the thermal efficiency of the new Dynamic Force engines. Toyota’s D-4S fuel injection incorporates both direct and port injection, the two systems combining to provide greater efficiency and smoother operation during normal driving but relying solely on direct injection when maximum power is needed. Meanwhile, the pistons themselves have a special finish to reduce friction, an electronic thermostat works in concert with an electric water pump to regulate temperature for peak efficiency, variable valve timing ensures optimal power vs. efficiency, and a higher compression ratio further increases efficiency. All these strategies culminate in a world-best 41% thermal efficiency in hybrid applications and 40% in gas-only vehicles, with more torque and power at any engine speed, and better fuel efficiency and emissions.

When it comes to the efficiency race, Toyota is fighting for every percent, and their new Dynamic Force engines now claim the gold medal in thermal efficiency. The hybrid version can be up to 41% and the standard version in the upcoming 2019 Corolla Hatchback has 40% thermal efficiency, and innovations such as the valve seat and high-speed combustion are like a new kick in a swimmer’s stroke that will help them outperform the competition.